The Importance of Materials Science in Advancing Robotics Evolution

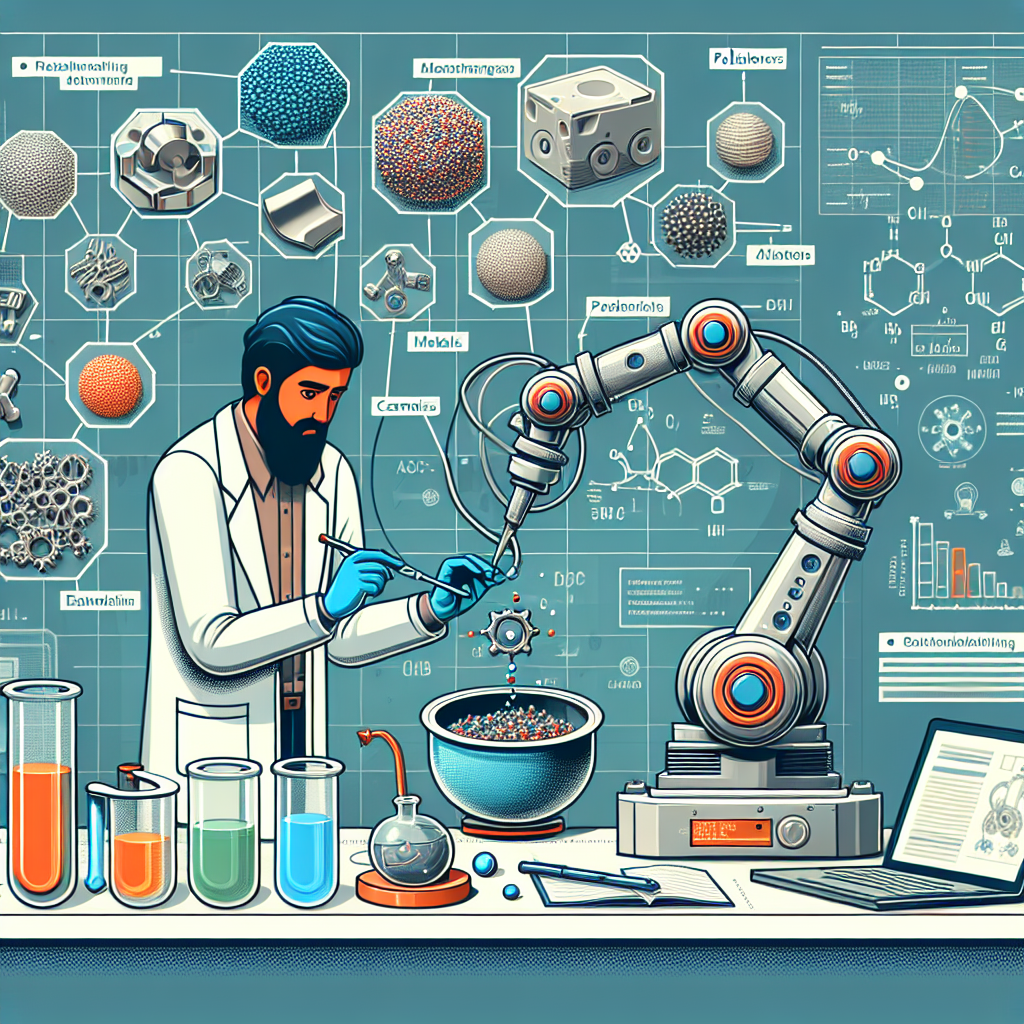

materials science plays a crucial role in the continuous evolution of robotics technology. By understanding the properties of different materials and selecting the most suitable ones, researchers and engineers can enhance the performance, durability, and functionality of robotic systems. Recent advancements in materials science, such as the development of nanomaterials and smart materials, have opened up new possibilities for robotics applications. However, challenges in ensuring durability and integrating materials with robotics systems remain. Looking ahead, the use of bio-inspired materials and materials for autonomous robotics holds promise for the future of robotics development.

Introduction

Materials science and robotics are two fields that have become increasingly intertwined in recent years, driving innovation and pushing the boundaries of what is possible in the realm of robotics technology. This section will provide an overview of the relationship between materials science and robotics, highlighting the key role that materials play in the development and advancement of robotic systems.

Overview of Materials Science and Robotics

Materials science is the study of the properties and characteristics of materials, as well as how they can be manipulated and utilized for various applications. In the context of robotics, materials science is essential for creating robotic components that are lightweight, durable, and capable of withstanding the rigors of different environments and tasks.

Robotics, on the other hand, is the field of engineering and technology that deals with the design, construction, operation, and application of robots. Robots are increasingly being used in a wide range of industries and settings, from Manufacturing and healthcare to exploration and entertainment.

By combining the principles of materials science with the advancements in robotics technology, researchers and engineers are able to create robots that are more efficient, versatile, and capable of performing complex tasks. The selection of the right materials is crucial in ensuring that robotic systems can meet the demands of their intended applications and environments.

Role of Materials in Robotics Development

Materials play a crucial role in the development of robotics technology, influencing the performance, durability, and functionality of robotic systems. Understanding the properties of different materials is essential for creating components that can withstand the demands of various environments and tasks.

Understanding Material Properties

Materials science involves studying the characteristics and behaviors of different materials, such as metals, polymers, and composites. By understanding these properties, researchers and engineers can determine which materials are best suited for specific robotic applications.

For example, the tensile strength, flexibility, and thermal conductivity of a material can Impact how well it performs in a robotic arm or a mobile robot chassis. By selecting materials with the right properties, engineers can optimize the performance and longevity of robotic systems.

Importance of Material Selection in Robotics

The selection of materials is a critical aspect of robotics development, as it directly influences the overall performance and capabilities of a robot. Choosing the right materials can enhance the efficiency, Reliability, and Safety of robotic systems.

Factors such as weight, cost, and environmental resistance must be considered when selecting materials for robotics applications. For example, lightweight materials like carbon fiber are often used in drones and robotic exoskeletons to improve agility and energy efficiency. On the other hand, materials like stainless steel are chosen for their durability and corrosion resistance in harsh environments.

Recent Advancements in Materials Science for Robotics

Impact of Nanomaterials on Robotics

Nanomaterials have revolutionized the field of robotics by offering unique properties and capabilities that traditional materials cannot match. These materials, which are typically on the nanometer scale, exhibit extraordinary strength, flexibility, and conductivity, making them ideal for enhancing the performance and functionality of robotic systems.

One of the key advantages of nanomaterials is their high surface area-to-volume ratio, which allows for increased reactivity and responsiveness in robotic components. This property enables robots to operate more efficiently and effectively in various tasks, from precision manufacturing to delicate surgical procedures.

Furthermore, nanomaterials can be engineered to have specific properties tailored to the needs of different robotic applications. For example, carbon nanotubes can be used to create lightweight yet strong robotic limbs, while graphene-based materials can provide exceptional electrical conductivity for advanced sensor systems.

Innovations in Smart Materials for Robotics

Smart materials are another groundbreaking development in materials science that is transforming the capabilities of robotic systems. These materials have the ability to respond to external stimuli, such as temperature, light, or pressure, and adapt their properties accordingly. This responsiveness allows for real-time adjustments and optimizations in robotic performance.

Shape memory alloys, for instance, can change shape in response to temperature changes, enabling robots to morph and adapt to different environments. Similarly, piezoelectric materials can generate electrical signals in response to mechanical stress, providing robots with self-sensing capabilities for improved feedback and control.

The integration of smart materials into robotics opens up new possibilities for creating adaptive and autonomous systems that can learn, evolve, and respond dynamically to changing conditions. By leveraging the unique properties of smart materials, researchers are pushing the boundaries of what robots can achieve in terms of versatility, intelligence, and efficiency.

Challenges and Opportunities in Materials Science for Robotics

Materials science in robotics presents a myriad of challenges and opportunities that researchers and engineers must navigate to advance the field. From ensuring durability and longevity to overcoming integration hurdles, the intersection of materials science and robotics is a complex yet promising landscape.

Ensuring Durability and Longevity

One of the primary challenges in materials science for robotics is ensuring the durability and longevity of robotic systems. Robots are often subjected to harsh environments and demanding tasks, which can put significant strain on their components. Therefore, selecting materials that can withstand wear and tear over extended periods is crucial for the reliability and performance of robots.

Factors such as mechanical stress, temperature fluctuations, and exposure to corrosive substances can all impact the durability of robotic materials. Researchers are constantly exploring new materials and coatings that can enhance the resilience of robotic components, ultimately prolonging the lifespan of robots and reducing maintenance costs.

Challenges in Material Integration with Robotics Systems

Another key challenge in materials science for robotics is the seamless integration of materials with robotic systems. The compatibility between materials and robotic components is essential for ensuring optimal performance and functionality. However, integrating diverse materials, each with its own unique properties and behaviors, can be a complex and intricate process.

Issues such as mismatched thermal expansion coefficients, inadequate bonding techniques, and limited material compatibility can hinder the successful integration of materials in robotics. Overcoming these challenges requires interdisciplinary collaboration between materials scientists, mechanical engineers, and robotics experts to develop innovative solutions that optimize the performance of robotic systems.

Future Directions and Possibilities

Bio-inspired Materials for Robotics

The field of robotics is increasingly turning to nature for inspiration in the development of new materials. Bio-inspired materials mimic the structures and properties found in living organisms, offering unique advantages for robotic systems. By studying how natural materials such as spider silk, gecko feet, and bone structure function, researchers can create synthetic materials that exhibit similar characteristics.

For example, researchers have developed adhesives inspired by gecko feet that allow robots to climb walls and ceilings with ease. By understanding the microscopic structures that enable geckos to stick to surfaces, engineers have been able to design materials that provide strong yet reversible adhesion for robotic applications.

Bio-inspired materials can also enhance the flexibility and adaptability of robots, allowing them to navigate complex environments and perform delicate tasks with precision. By incorporating principles from nature into materials design, researchers are unlocking new possibilities for the next generation of robotic systems.

Materials for Autonomous Robotics

Autonomous robotics, which refers to robots that can operate independently without human intervention, rely on advanced materials to enable self-sufficiency and intelligence. Materials for autonomous robotics must possess properties that allow for sensing, decision-making, and actuation without external control.

One key area of focus for materials in autonomous robotics is the development of sensors that can detect and respond to the robot’s surroundings. Smart materials with built-in sensors and actuators enable robots to perceive their environment, make decisions based on real-time data, and adapt their behavior accordingly.

Furthermore, materials that enable energy harvesting and storage are essential for autonomous robots to operate continuously without the need for frequent recharging or external power sources. By integrating materials that can convert ambient energy into usable power, researchers are paving the way for autonomous robots that can sustain long-term operations in remote or challenging environments.

Conclusion

In conclusion, the relationship between materials science and robotics is a dynamic and evolving one that is driving innovation and shaping the future of robotic technology. The role of materials in robotics development cannot be overstated, as they are essential for enhancing the performance, durability, and functionality of robotic systems.

Recent advancements in materials science, such as the development of nanomaterials and smart materials, have opened up new possibilities for robotics applications. Nanomaterials offer unique properties like extraordinary strength and flexibility, while smart materials can respond to external stimuli and adapt their properties, enabling robots to operate more efficiently and effectively.

Challenges in materials science for robotics, such as ensuring durability and integrating materials with robotic systems, present opportunities for researchers and engineers to push the boundaries of what is possible in the field. By overcoming these challenges through interdisciplinary collaboration and innovative solutions, the future of robotics development looks promising.

Looking ahead, the use of bio-inspired materials and materials for autonomous robotics holds great potential for the next generation of robotic systems. By drawing inspiration from nature and leveraging advanced materials that enable self-sufficiency and intelligence, researchers are paving the way for autonomous robots that can navigate complex environments and sustain long-term operations.

Overall, the intersection of materials science and robotics is a complex yet exciting landscape that continues to shape the evolution of robotic technology. By understanding the properties of different materials, selecting the most suitable ones, and pushing the boundaries of materials science, researchers and engineers are driving the advancement of robotics technology towards a future full of possibilities.

Comments