Innovating Production Efficiency with Smart Factories and AI: Evolution of Technology Shaping the Future

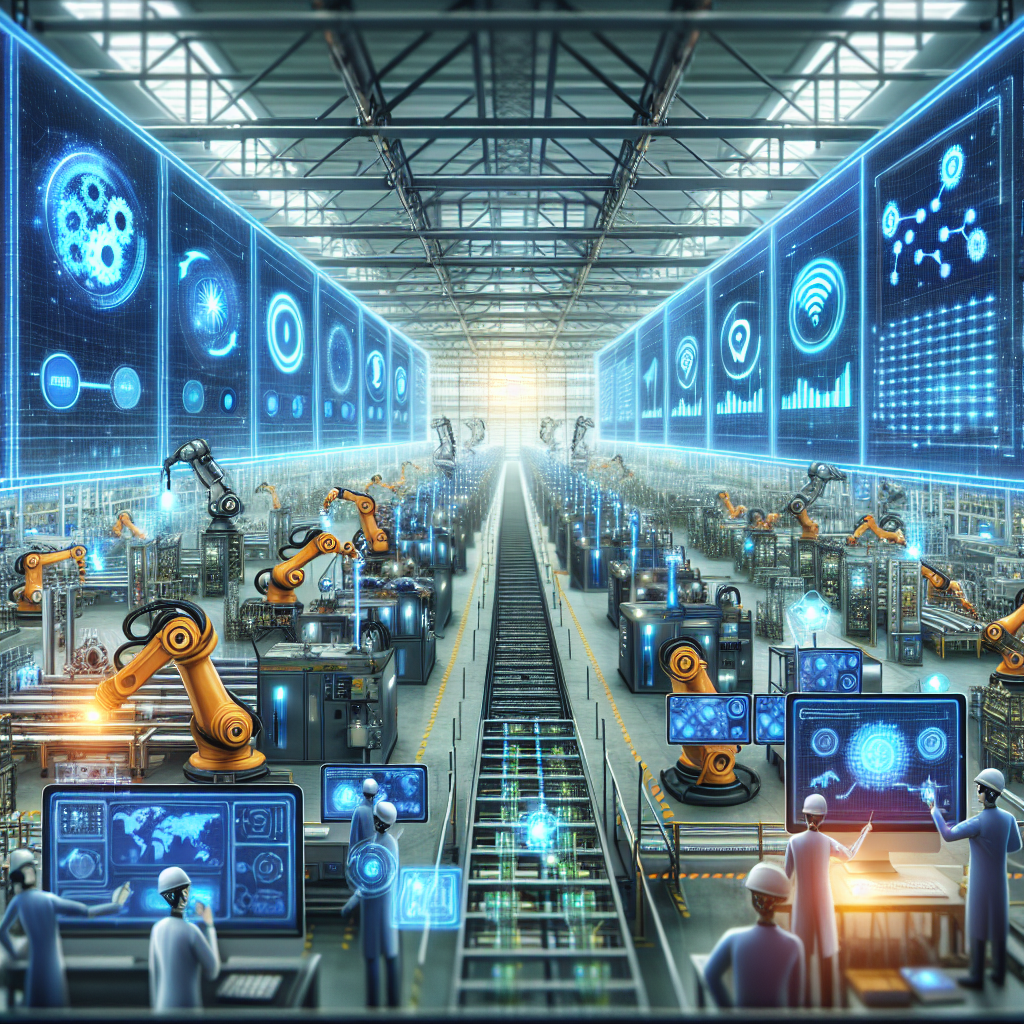

The integration of smart factories and artificial intelligence (AI) is revolutionizing the Manufacturing industry, leading to increased production efficiency and shaping the future of technology in production processes.

Introduction

Welcome to the introduction section where we will provide an overview of the integration of smart factories and artificial intelligence (AI). This integration is at the forefront of revolutionizing the manufacturing industry, leading to increased production efficiency and shaping the future of technology in production processes.

Overview of Smart Factories and AI Integration

In this section, we will delve into the key aspects of smart factories and AI integration that are driving the evolution of technology in manufacturing. Smart factories are a crucial component of industry 4.0, the ongoing revolution in manufacturing that emphasizes automation, interconnectivity, and data exchange.

Industry 4.0 is characterized by the adoption of advanced technologies such as artificial intelligence, machine learning, and the internet of things (IoT) to create smart, connected production systems. Automation in manufacturing plays a significant role in improving efficiency and reducing human intervention in repetitive tasks.

The interconnectivity of machines in smart factories enables seamless communication and collaboration between different components of the production process. This Connectivity allows for real-time data exchange and decision-making, leading to optimized production workflows and enhanced productivity.

Artificial intelligence is another key technology driving the evolution of manufacturing. Machine learning applications in manufacturing enable machines to learn from data, identify patterns, and make decisions without human intervention. Predictive maintenance systems powered by AI can anticipate equipment failures before they occur, reducing downtime and maintenance costs.

AI-driven quality control systems use advanced algorithms to inspect products for defects and ensure high-quality standards are met. The integration of smart factories and AI brings together the power of data analytics, real-time monitoring, and collaborative robots to streamline production processes and improve overall efficiency.

As we explore the benefits, challenges, and future trends of smart factories and AI integration, it becomes evident that this technological evolution is reshaping the manufacturing landscape and paving the way for a more efficient and agile industry.

Smart Factories

Smart factories are at the forefront of revolutionizing the manufacturing industry by incorporating advanced technologies such as artificial intelligence and automation. These factories leverage cutting-edge solutions to enhance production efficiency and drive innovation in the manufacturing sector.

Industry 4.0 Revolution

The Industry 4.0 revolution represents a paradigm shift in manufacturing, emphasizing the integration of digital technologies to create smart, interconnected production systems. Smart factories are a key component of this revolution, enabling manufacturers to optimize processes, improve quality, and respond quickly to market demands.

Automation in Manufacturing

Automation plays a crucial role in smart factories, allowing for the seamless execution of repetitive tasks with precision and efficiency. By automating processes, manufacturers can reduce human error, increase productivity, and achieve consistent output quality across production lines.

Interconnectivity of Machines

The interconnectivity of machines within smart factories enables seamless communication and collaboration between different components of the production process. This interconnected network facilitates real-time data exchange, enabling machines to work in harmony and make informed decisions to optimize production workflows.

Overall, the integration of smart factories and AI is driving the evolution of technology in manufacturing, paving the way for a more efficient, agile, and innovative industry.

Artificial Intelligence in Manufacturing

Artificial intelligence (AI) is revolutionizing the manufacturing industry by enabling machines to perform tasks that typically require human intelligence. In the context of manufacturing, AI is being used to enhance efficiency, quality control, and predictive maintenance systems.

Machine Learning Applications

Machine learning, a subset of AI, is a powerful tool in manufacturing that allows machines to learn from data and improve their performance over time. In production processes, machine learning applications can analyze large datasets to identify patterns, optimize workflows, and make real-time decisions without human intervention.

For example, in a smart factory setting, machine learning algorithms can analyze historical production data to predict equipment failures, optimize maintenance schedules, and prevent costly downtime. By continuously learning from new data, machine learning models can adapt and improve their predictions, leading to more efficient and reliable manufacturing operations.

Predictive Maintenance Systems

Predictive maintenance systems powered by AI are transforming the way manufacturers approach equipment maintenance. By leveraging machine learning algorithms and real-time sensor data, predictive maintenance systems can predict when a machine is likely to fail and proactively schedule maintenance before a breakdown occurs.

This proactive approach to maintenance not only reduces unplanned downtime but also extends the lifespan of equipment, reduces maintenance costs, and improves overall production efficiency. By implementing predictive maintenance systems, manufacturers can shift from reactive, time-based maintenance schedules to a more efficient and cost-effective predictive maintenance strategy.

AI-driven Quality Control

Quality control is a critical aspect of manufacturing, ensuring that products meet the required standards of quality and Safety. AI-driven quality control systems use advanced algorithms to inspect products for defects, anomalies, and deviations from specifications.

By integrating AI into quality control processes, manufacturers can improve product consistency, reduce waste, and enhance customer satisfaction. AI-powered quality control systems can analyze images, sensor data, and other inputs to detect defects in real-time, enabling manufacturers to take corrective actions before defective products reach the market.

Overall, the integration of AI in manufacturing is driving significant improvements in efficiency, quality, and maintenance practices, shaping the future of technology in production processes.

Integration of Smart Factories and AI

Smart factories and artificial intelligence (AI) are becoming increasingly integrated to enhance production processes and drive efficiency in manufacturing. The seamless integration of these technologies is transforming the way factories operate, leading to optimized workflows and improved productivity.

Data Analytics for Efficiency

data analytics plays a crucial role in smart factories by enabling manufacturers to gain valuable insights from the vast amounts of data generated during production. By analyzing this data, companies can identify patterns, trends, and areas for improvement, ultimately leading to more efficient and informed decision-making.

Through data analytics, manufacturers can optimize production schedules, predict maintenance needs, and identify opportunities for cost reduction. This data-driven approach allows companies to streamline operations, reduce waste, and maximize the use of resources, ultimately improving overall efficiency in manufacturing processes.

Real-time Monitoring and Control

Real-time monitoring and control are essential components of smart factories that enable manufacturers to oversee production processes in real-time. By utilizing sensors and connected devices, companies can track key performance indicators, monitor equipment status, and make immediate adjustments to optimize production efficiency.

Real-time monitoring allows manufacturers to identify issues as they arise, preventing costly downtime and ensuring that production runs smoothly. By having instant access to critical data, companies can make informed decisions quickly, leading to improved productivity and reduced operational risks.

Collaborative Robots in Production

Collaborative robots, also known as cobots, are increasingly being used in smart factories to work alongside human operators and automate repetitive tasks. These robots are designed to be safe, flexible, and easy to program, making them ideal for a wide range of manufacturing applications.

By integrating collaborative robots into production lines, manufacturers can increase efficiency, improve quality, and enhance worker safety. These robots can perform tasks that are dull, dirty, or dangerous for humans, allowing employees to focus on more complex and value-added activities.

Overall, the integration of smart factories and AI, including data analytics, real-time monitoring, and collaborative robots, is driving significant advancements in manufacturing processes. By leveraging these technologies, companies can achieve higher levels of efficiency, quality, and innovation, ultimately shaping the future of production in the industry.

Benefits of Smart Factories and AI

Improved Production Efficiency

One of the key benefits of integrating smart factories and AI in manufacturing is the significant improvement in production efficiency. By automating processes, optimizing workflows, and reducing human intervention in repetitive tasks, smart factories can operate at higher speeds and with greater precision.

The use of artificial intelligence in production processes allows machines to learn from data, identify patterns, and make decisions without human intervention. This leads to streamlined operations, reduced errors, and increased output quality, ultimately enhancing overall efficiency in manufacturing.

Through the interconnectivity of machines in smart factories, real-time data exchange and decision-making enable optimized production workflows and enhanced productivity. This seamless communication between different components of the production process ensures that operations run smoothly and efficiently.

Cost Reduction and Resource Optimization

Another significant benefit of smart factories and AI integration is the potential for cost reduction and resource optimization in manufacturing. By leveraging advanced technologies such as artificial intelligence, machine learning, and the Internet of Things, companies can identify inefficiencies, reduce waste, and maximize the use of resources.

AI-driven predictive maintenance systems can anticipate equipment failures before they occur, reducing downtime and maintenance costs. By proactively scheduling maintenance based on real-time data and machine learning algorithms, manufacturers can extend the lifespan of equipment and minimize costly repairs.

Furthermore, the use of collaborative robots in production lines can help optimize labor costs and improve efficiency. These robots can perform repetitive tasks with precision, freeing up human operators to focus on more complex and value-added activities, ultimately reducing operational costs and increasing productivity.

Enhanced Flexibility in Manufacturing

Smart factories and AI integration also offer enhanced flexibility in manufacturing processes, allowing companies to adapt quickly to changing market demands and production requirements. By utilizing data analytics, real-time monitoring, and collaborative robots, manufacturers can respond swiftly to fluctuations in demand and optimize production schedules.

The interconnectivity of machines in smart factories enables seamless communication and collaboration, facilitating agile decision-making and adjustments to production workflows. This flexibility allows manufacturers to scale operations up or down as needed, ensuring efficient use of resources and maximizing productivity.

Overall, the benefits of integrating smart factories and AI in manufacturing are clear: improved production efficiency, cost reduction, resource optimization, and enhanced flexibility. By embracing these technologies, companies can stay competitive, drive innovation, and shape the future of technology in production processes.

Challenges and Considerations

Cybersecurity Risks

One of the key challenges in integrating smart factories and AI is the increased exposure to cybersecurity risks. As these systems become more interconnected and reliant on data exchange, they become vulnerable to cyber attacks that can disrupt production processes, steal sensitive information, or compromise the integrity of the manufacturing operations.

Manufacturers must implement robust cybersecurity measures to protect their smart factories and AI systems from potential threats. This includes implementing firewalls, encryption protocols, access controls, and regular security audits to identify and address vulnerabilities before they can be exploited by malicious actors.

Furthermore, the rapid pace of technological advancements in smart factories and AI means that cybersecurity measures must be continuously updated and improved to stay ahead of evolving threats. Manufacturers must invest in cybersecurity training for their employees and stay informed about the latest cybersecurity trends and best practices to mitigate risks effectively.

Impact on Workforce and Skills

The integration of smart factories and AI also raises concerns about the Impact on the existing workforce and the skills required to operate and maintain these advanced technologies. As automation and AI-driven systems take over repetitive tasks, there is a growing need for workers to acquire new skills and adapt to the changing nature of manufacturing jobs.

Manufacturers must invest in training programs to upskill their workforce and ensure that employees are equipped to work alongside AI systems and collaborative robots. This includes training in data analytics, programming, cybersecurity, and other relevant skills that are essential for operating smart factories efficiently.

At the same time, manufacturers must address concerns about job displacement and ensure that workers are not left behind as technology advances. This may involve retraining programs, job rotation opportunities, and creating new roles that leverage human creativity, problem-solving skills, and emotional intelligence – areas where humans still excel over machines.

Implementation Challenges

Implementing smart factories and AI systems in manufacturing poses several challenges that manufacturers must overcome to ensure successful integration and operation. One of the key implementation challenges is the high upfront costs associated with acquiring and deploying advanced technologies such as AI, machine learning, and IoT devices.

Manufacturers must carefully evaluate the return on investment (ROI) of implementing smart factories and AI to justify the initial expenses and secure buy-in from stakeholders. This may involve conducting pilot projects, demonstrating proof of concept, and showcasing the tangible benefits of increased production efficiency, cost reduction, and quality improvement that these technologies can deliver.

Another implementation challenge is the complexity of integrating disparate systems, legacy equipment, and software platforms into a unified smart factory ecosystem. Manufacturers must ensure compatibility, interoperability, and seamless data exchange between different components of the production process to maximize the benefits of automation, connectivity, and AI-driven decision-making.

Furthermore, manufacturers must address regulatory compliance requirements, data privacy concerns, and ethical considerations related to the use of AI in manufacturing. This includes ensuring that AI algorithms are transparent, accountable, and unbiased in their decision-making processes to maintain trust and integrity in the manufacturing operations.

Future Trends and Innovations

Integration with Internet of Things (IoT)

One of the key future trends in the integration of smart factories and AI is the advancement of Internet of Things (IoT) technology. IoT devices play a crucial role in connecting machines, sensors, and other components within smart factories, enabling real-time data exchange and communication.

By integrating AI with IoT devices, manufacturers can create intelligent systems that can analyze data, make decisions, and optimize production processes autonomously. This integration allows for predictive maintenance, remote monitoring, and enhanced control over manufacturing operations, leading to increased efficiency and reduced downtime.

As iot technology continues to evolve, we can expect to see more sophisticated sensors, actuators, and devices that can collect and transmit data in real-time. This data can be leveraged by AI algorithms to drive insights, improve decision-making, and ultimately enhance the overall performance of smart factories.

Furthermore, the integration of IoT with AI opens up new possibilities for smart factories, such as the development of digital twins – virtual replicas of physical assets or processes that can be used for simulation, analysis, and optimization. These digital twins can provide valuable insights into production workflows, identify potential bottlenecks, and enable predictive maintenance strategies.

Advancements in Digital Twin Technology

Another exciting future trend in the integration of smart factories and AI is the advancements in digital twin technology. Digital twins are virtual models that replicate physical assets, processes, or systems, allowing manufacturers to simulate and optimize production operations in a virtual environment.

By creating digital twins of manufacturing equipment, production lines, or entire factories, manufacturers can conduct virtual tests, predict performance outcomes, and identify areas for improvement without disrupting actual production processes. This technology enables companies to optimize workflows, reduce downtime, and enhance overall efficiency in manufacturing.

With the advancement of AI algorithms and machine learning techniques, digital twins are becoming more sophisticated and capable of providing real-time insights into production processes. Manufacturers can leverage these digital replicas to monitor equipment health, predict failures, and optimize maintenance schedules, ultimately improving operational efficiency and reducing costs.

As digital twin technology continues to evolve, we can expect to see increased adoption in smart factories, leading to more agile, data-driven decision-making processes. By integrating digital twins with AI-powered analytics, manufacturers can gain a competitive edge by optimizing production workflows, improving quality control, and responding quickly to changing market demands.

Edge Computing for Real-time Processing

edge computing is another future trend that is set to revolutionize the integration of smart factories and AI by enabling real-time data processing and analysis at the edge of the network. In traditional cloud computing models, data is sent to centralized servers for processing, which can introduce latency and bandwidth constraints.

With edge computing, data processing is moved closer to the data source, allowing for faster response times, reduced latency, and improved Reliability in processing real-time data streams. This technology is particularly beneficial for smart factories, where immediate decision-making is critical for optimizing production processes and ensuring operational efficiency.

By deploying edge computing solutions in smart factories, manufacturers can analyze sensor data, machine metrics, and production information in real-time, enabling AI algorithms to make instant decisions and adjustments. This real-time processing capability enhances predictive maintenance, quality control, and overall operational efficiency in manufacturing.

As edge computing technologies continue to mature, we can expect to see increased adoption in smart factories, leading to more agile and responsive production systems. By leveraging edge computing for real-time processing, manufacturers can unlock new opportunities for automation, optimization, and innovation in manufacturing processes.

Conclusion

The integration of smart factories and artificial intelligence is reshaping the manufacturing industry, driving significant advancements in production efficiency, quality control, and predictive maintenance. By leveraging advanced technologies such as AI, machine learning, and the Internet of Things, manufacturers can optimize workflows, reduce costs, and enhance flexibility in production processes.

Smart factories are at the forefront of this technological evolution, enabling seamless communication between machines, real-time data exchange, and collaborative decision-making. The adoption of AI-driven quality control systems, predictive maintenance strategies, and collaborative robots is revolutionizing the way factories operate, leading to increased productivity and innovation in manufacturing.

While there are challenges to overcome, such as cybersecurity risks, workforce adaptation, and implementation complexities, the benefits of integrating smart factories and AI are clear. Improved production efficiency, cost reduction, resource optimization, and enhanced flexibility are driving the future of technology in production processes.

As we look ahead, future trends such as the integration of IoT, advancements in digital twin technology, and the adoption of edge computing are set to further enhance the capabilities of smart factories and AI in manufacturing. By embracing these innovations, companies can stay competitive, drive innovation, and shape the future of production in the industry.

Comments